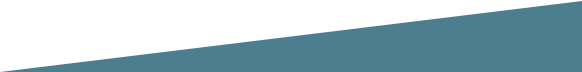

Software

Ansys

Sub-resellers

Founded in 1970, Ansys software has enabled innovators across industries to push boundaries with the predictive power of simulation. From sustainable transportation and advanced semiconductors to satellite systems and life-saving medical devices, the next great leaps in human advancement will be powered by Ansys.

ANSYS is the best simulation software which enables organizations to confidently predict how their products will operate in the real world. We believe that every product is a promise of something greater.

Simulation-Driven Product Development takes engineering simulation to another level-the unequalled depth and breadth of our best 3d software coupled with its unmatched engineered scalability, comprehensive multiphysics foundation and adaptive architecture set our technology apart from other CAE tools. These ANSYS advantages add value to the engineering design process by delivering efficiency, driving innovation and reducing physical constraints, enabling simulated tests that might not be possible otherwise.

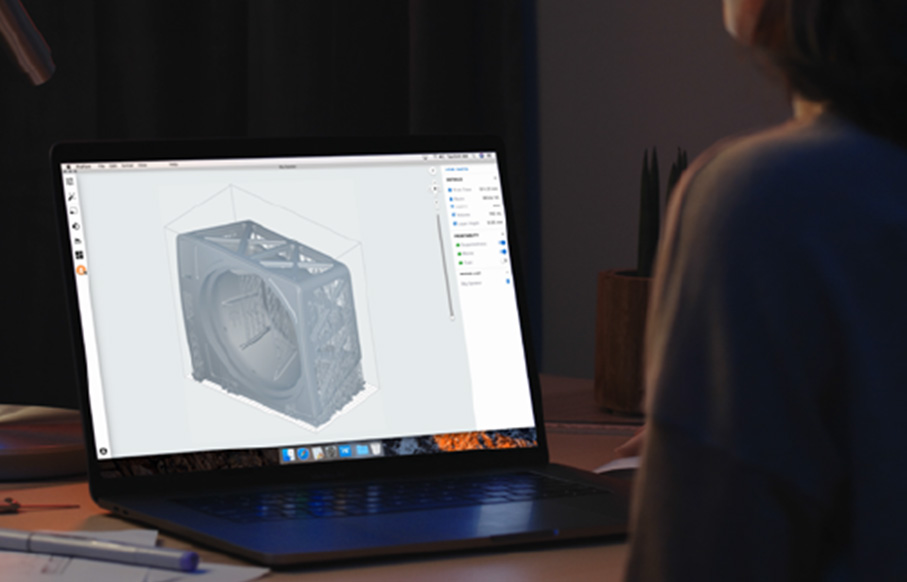

Instantaneous simulation results as models are designed and edited

Ansys Simulation software enables product development engineers to gain insights that were previously possible only through making and breaking expensive prototypes. However, such software isn’t for every engineer. With its Discovery Live technology, ANSYS revolutionizes product design. This 3D simulation software provides instantaneous simulation results while you design and edit and enables you to experiment with design ideas for on-the-spot feedback. These immediate insights make simulation useful and relevant to every engineer for upfront CAE. Discovery Live’s speed and simplicity represent a quantum leap forward in simulation technology, and it enables you to spend more time with answers instead of questions.

With Discovery Live, you can:

- Experiment with design ideas, easily make changes and receive instantaneous engineering insights

- Perform 10 to 1,000 simulations in the same timeframe that was once needed to perform just one simple simulation

- Simulate on newly created models or any imported CAD file

- Investigate more options earlier in the design process and develop new products that get to market faster

- Explore all your “what if” design ideas at little to no cost in time and effort

- Facilitate breakthroughs and innovations and take your engineering efforts to the next level